Carte+ Is The World’s

First Omni Rack Robotics (ORR) System

Automate the Racks

You Already Have

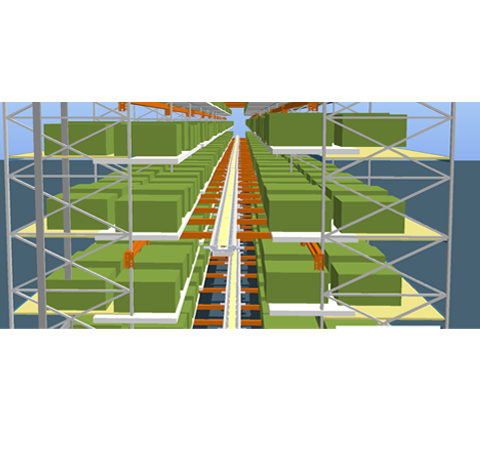

Carte+ is a high-performance picking and replenishment system designed to automate fulfillment—including reverse logistics—without rebuilding your warehouse. Developed by Cartesian Kinetics, Carte+ is the first solution in a new category of warehouse automation: Omni Rack Robotics (ORR). It works with standard racks, mezzanines, and high bays—no custom infrastructure, floor prep, or proprietary totes required

What It Does

Carte+ transforms static racking into a dynamic fulfillment engine, increasing throughput up to 5X. It’s fast to deploy (under 6 weeks), easy to scale (one aisle at a time), and requires minimal disruption. Whether you’re dealing with labor shortages, rising wages, or peak season volume surges—Carte+ fits.

Hardware Components

Robots

Smart, high-speed robot shuttles that travel horizontally and vertically to retrieve and deliver totes or cartons from any rack level. Designed to handle a wide range of SKUs and packaging types with speed and accuracy. Robot shuttles can deliver to pick walls, conveyor belts, or buffer zones depending on layout.

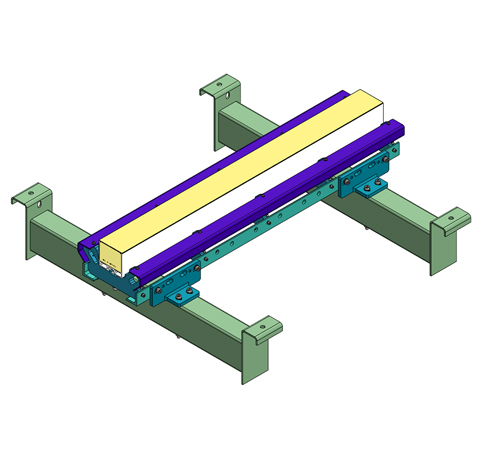

Rails

Simple, modular rail systems mount directly onto your existing racks—no rack replacement or floor anchoring required. These rails guide the shuttles between pick locations across multiple levels.

Bot Path

A powered overhead track that lets shuttles move between aisles. This overhead system eliminates floor traffic, increases safety, and opens space for human workflows or inventory staging below.

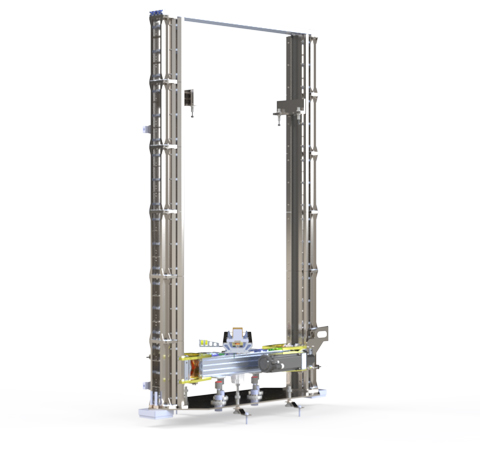

Lifts

Integrated vertical lifts enable seamless tote movement across rack levels—from ground-level bins to top-tier storage. Each lift is synchronized with the shuttle path for continuous movement and minimal dwell time.

Software + Intelligence

Smart Routing + Real-Time Coordination

Carte+ includes intelligent control software that adapts to changing order patterns, SKU mixes, and peak demand—all in real time. It integrates with existing WMS and OMS platforms or can run independently in standalone mode.

Multi-Modal Picking Support

Batch, wave, zone, or on-demand—Carte+ handles a variety of picking strategies with minimal configuration. Great for operations with hybrid fulfillment needs like B2C + B2B or store + ecomm.

The Digital Twin That De-Risks Automation

Carte+ includes a patented physical-digital twin: eCarte+.

This isn’t a theoretical simulation—it’s a fully synchronized model of your warehouse operation.

1

Run Real Order Data

2

ROI Validation

3

Virtual Commissioning

4

Bottleneck Detection

5

Faster Installs

Whether you’re scaling a grocery DC, retrofitting a 3PL, or automating a mezzanine, eCarte+ lets you validate every move before a single bolt is drilled.

Why Carte+ Works for More Facilities

Carte+ was built for the real world—brownfields, legacy racking, narrow aisles, mezzanines, and non-pristine floors. It combines the flexibility of AMRs with the efficiency of ASRS, without the constraints of either.

● Works with your existing infrastructure

● Handles your totes and cartons

● Scales one aisle at a time

● Installs in 4–6 weeks

Whether you’re running thousands of SKUs across mezzanine levels or retrofitting vertical storage in a high-bay zone, Carte+ adapts to your warehouse—not the other way around.